Dutch Freshkeeper broadly applicable

In the past decade several concepts to manage fresh and salt (brackish) groundwater more effectively and so improve the fresh water supply in delta areas have been developed. One of those concepts , the Freshkeeper, is also in focus internationally. Through public-private cooperation between KWR, Vitens, De Ruiter and ARCADIS this concept will in future be applied to coastal areas around the world.

Water, for use as drinking water, by the industry, and in agriculture, is scarce in the Dutch lowlands. That is due to the small amount of fresh groundwater in the mostly brackish subsurface. This is noticeable for instance in the dunes, where a large part of the drinking water of West-Netherlands is produced. Already since the 1950’s of the last century surface water is infiltrated in the dunes to complement the freshwater bell and prevent groundwater salinisation.

Groundwater production in the northern, middle and eastern part of the country are vulnerable too, due to fossil brackish water in the deeper soil. In 1993 drinking water company (later becoming) Vitens had to close the northern well field of groundwater supply Noardburgum (Friesland) because brackish groundwater was flowing to the freshwater abstraction wells. At that time no other solution was available.

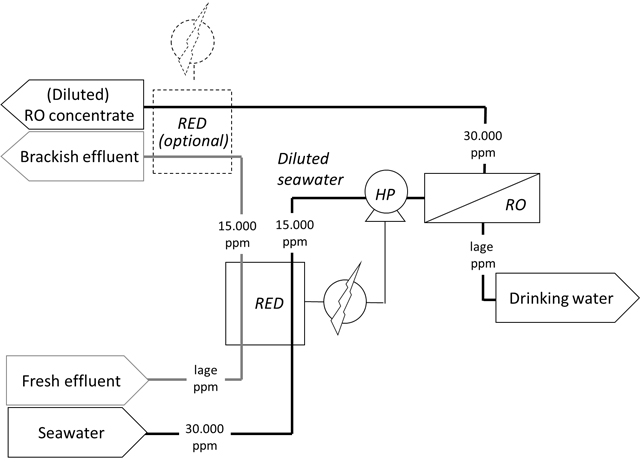

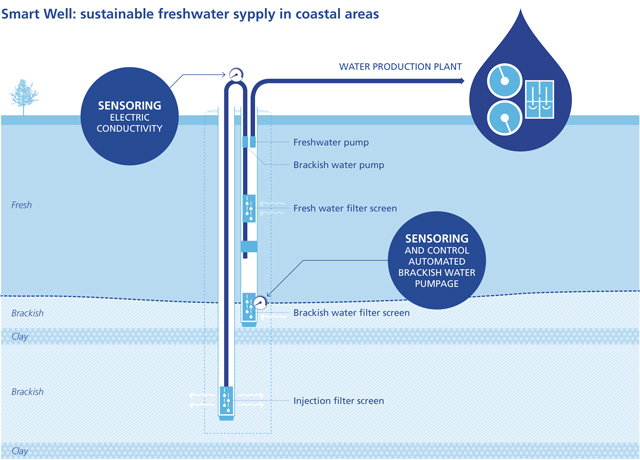

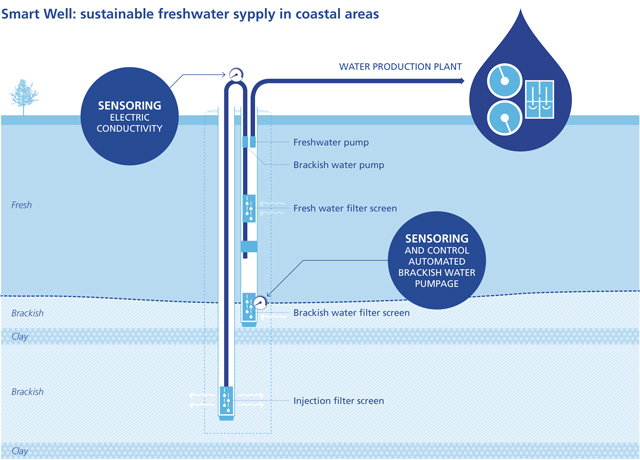

As a solution for salinisation of the groundwater production the idea of the Freshkeeper was developed early 2000. The principle here is that not only fresh groundwater is abstracted, but with a separate filter screen also the upconing brackish water. In that way the fresh-saline interface is stabilised, preventing salinisation of the fresh filter screen. The brackish groundwater can be disposed, for instance by injection into deeper aquifers, but it can also serve as an additional source for drinking water after desalination with reversed osmosis (RO). So theoretically it is possible to even enlarge the total production of a salinised well field, by using the fresh as well as the brackish water.

The smart Freshkeeper well of Noardburgum

The smart Freshkeeper well of Noardburgum

Practical field test

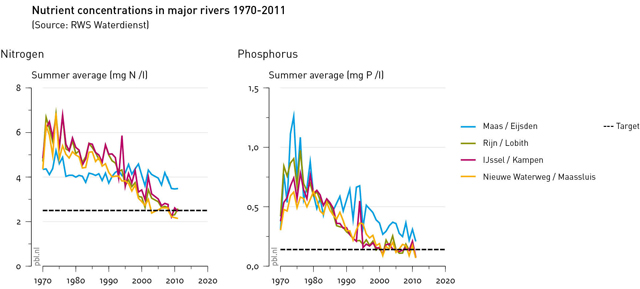

This Freshkeeper combined with brackish water RO was applied during a practical field test in the northern well field of Noardburgum in 2009 and 2010. Through the fresh as well as the brackish filter screen a fixed discharge of 50 cubic metres per hour water was won. The Freshkeeper was installed to stabilize the fresh-brackish interface, but with the configuration that was selected locally this interface was even pulled down. That became apparent from the decline in chloride concentrations in the several observation filters.

This downconing was acknowledged by calculations with Seawat, a density dependent groundwater flow model. Scenario calculations showed that the extraction of 16 cubic metres per hour from the brackish filter screen should be sufficient when from the fresh filter screen 50 cubic metres per hours is won.

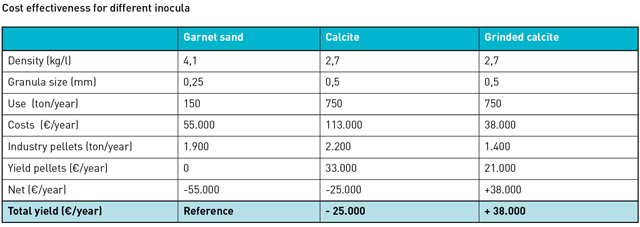

At the same time Brabant Water experimented with brackish water as a source for drinking water as well. Both practical tests provided much knowledge on the disposal of membrane concentrate through injection in below brackish aquifers. Concentrate is a residue of desalination and its disposal is an obstacle in the breakthrough of brackish groundwater as a freshwater source. In Noardburgum the concentrate injection appeared to be easily implemented, especially because of high iron concentration that disturbed calcite precipitation. Calcite precipitation did cause obstruction of the injection wells at Brabant Water, but this could be solved effectively by adding the weak acid CO2 to the concentrate.

Conclusion of the practical test at Noardburgum in 2009 and 2010 was that a relatively large abstraction of brackish water against the abstraction of freshwater had even realised a freshening of the groundwater system. That made evident that a further optimisation of the Freshkeeper was possible.

Optimization

This optimization is taking place within the TKI Watertechnology-project Keep It Fresh!. Vitens, De Ruiter Grondwatertechniek (formerly BAM Nelis de Ruiter) and KWR are cooperating on the development of a ‘smart well’. In this Freshkeeper-well two abstraction filters are located in a depth of 60 metres (fresh groundwater) and 140 metres (brackish groundwater). The brackish water is pumped up at the same time as the fresh water, but subsequently injected on a depth of 170 metres under a confining clay layer. The smart part is in the measurement and control technology. The well itself determines, based on online measurements of the salinity of the groundwater, how much groundwater is pumped. In this way the energy costs for the disposal of brackish groundwater can be minimalized while the freshwater production remains fresh.

The smart well has shortly become operational and will be tested extensively in 2015. Not only regarding the technical functioning of the well itself, but also with respect to the reaction of the groundwater system on different abstraction regimes of fresh and brackish groundwater. The produced information will be used to develop a good density dependent groundwater flow model and for selection of the decision making rules to full automatically manage the well. This knowledge is supposed to be the prelude to a full scale application of the Freshkeeper concept an re-opening of the northern well field of Noardburgum that was closed in 1993.

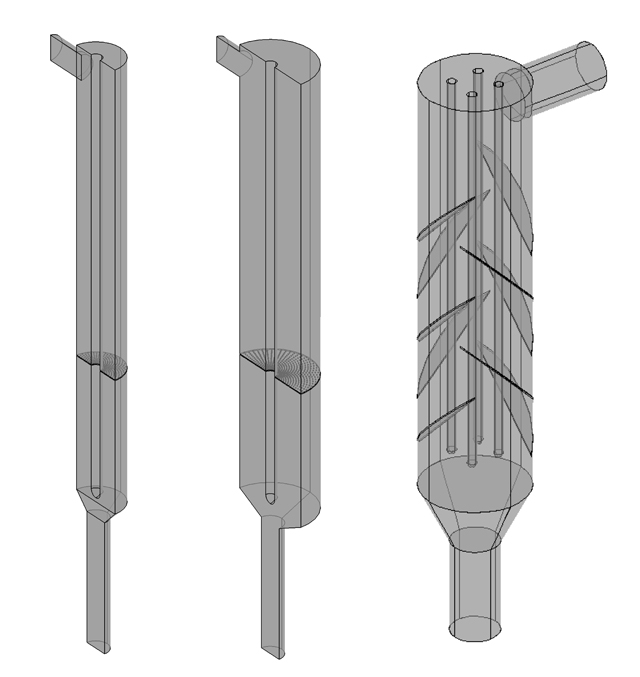

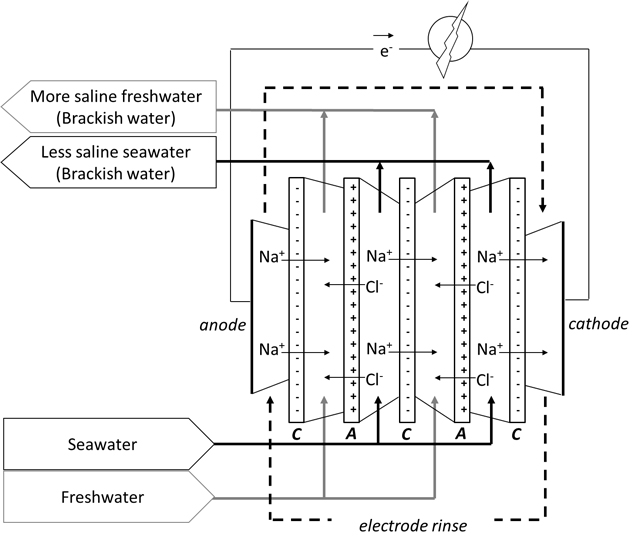

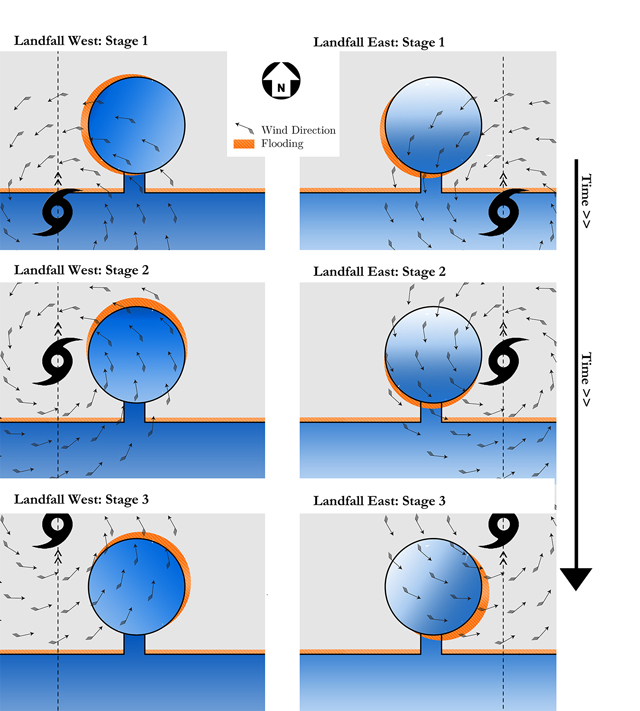

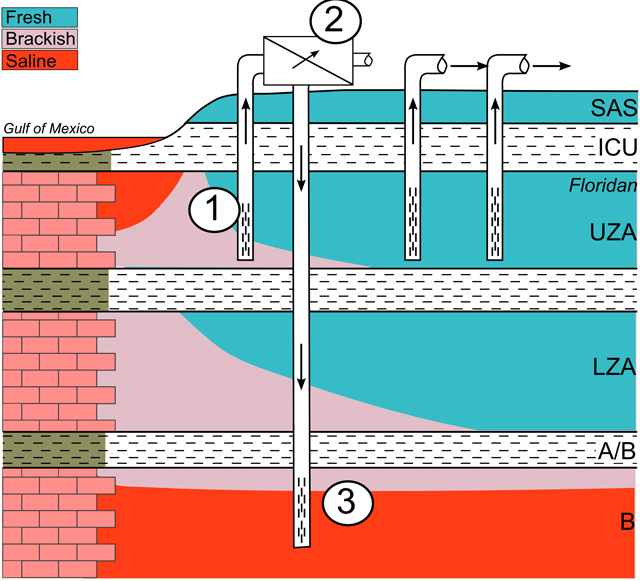

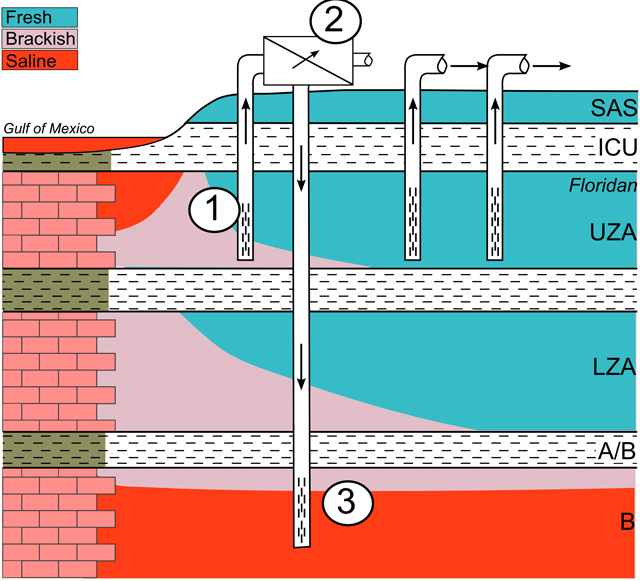

Scheme of possible applications of the Freshkeeper in Florida.

Scheme of possible applications of the Freshkeeper in Florida.

The freshwater wells inland are protected by interception of the intruding seawater (1). The intercepted water is desalinated with reversed osmoses (RO ) (2), after which the membrane concentrate is disposed to the underlying aquifer.

Export

The idea of the smart well was conceived by Vitens and further implemented with both project partners. The control and measurement technology of the well is for a larger part developed by De Ruiter Grondwatertechniek, KWR brings in knowledge of density dependent groundwater flow. De Ruiter foresees many opportunities for the application of the concept outside of the Netherlands. Salinisation is a global problem and Freshkeeper is a, essentially simple, solution that is also applicable elsewhere in Europe or in the United States. It is a challenge to apply the innovation in countries that are less developed regarding control and measurement technology such as Indonesia and Suriname.

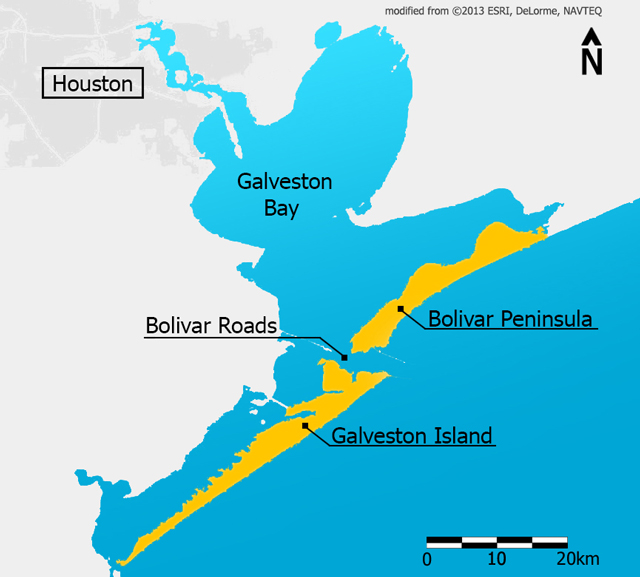

Export chances might occur in short term. In the past year ARCADIS, KWR en Vitens have executed feasibility studies in the US, additionally supported by the Dutch Climate Changes Spatial Planning Programme. The studies were commissioned by two water companies in Florida, also experiencing salinisation of their drinking water production, both by the upconing of (fossil) brackish groundwater as by intrusion of saltwater from the sea. An important difference with the Dutch situation is the local geology. The Netherlands is a young delta area, built alternately from sand and clay. The subsurface of Florida for a larger part consists of limestone, often with a complex groundwater flow.

The feasibility studies indicated the economic advantages of Freshkeeper with respect to other options, such as (full) conversion to brackish water RO that is becoming increasingly popular in Florida. The following step is the actual application of the Freshkeeper in a pilot test. For this ARCADIS and KWR have recently designed a project plan together with a west coastal water company.

In 2015 feasibility studies on the application of Freshkeeper as well as other innovative concepts for freshwater management in Mexico and Chili start, as part of the Securing Water for Food programme of the US Agency for International Development (USAID), the Swedish SIDA and the Dutch Ministry of Foreign Affairs. The European Commission (EC) recently approved SUBSOL, an R&D project that foresees replication pilots in the Netherlands, Denmark, Greece and the US.

The EC, USAID and its partners thus recognise the need to find sustainable solutions for freshwater supply in coastal areas as a counter-reaction to the worldwide increasing groundwater salinisation. In their view Freshkeeper and other Subsurface Water Technologies (SWT) are effective, cost efficient and robust fresh water solutions.

Klaasjan Raat

(KWR Watercycle Research Institute)

Ate Oosterhof

(Vitens)

Frans Heinis

(De Ruiter Grondwatertechniek)

Petra Ross

(ARCADIS)

Additional new concepts for freshwater management

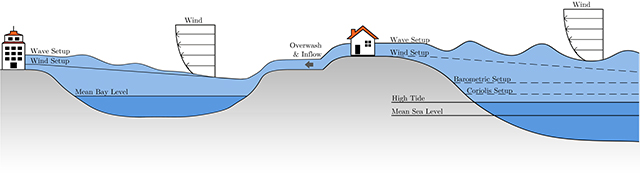

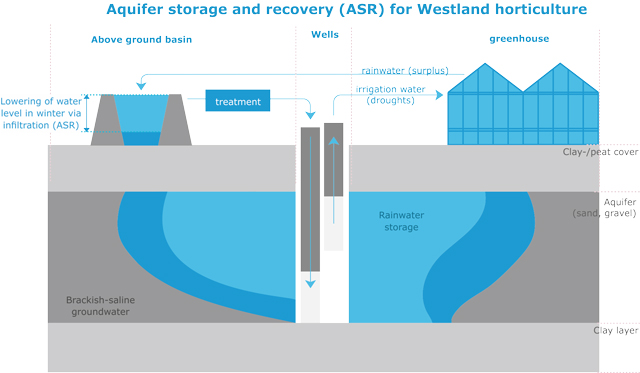

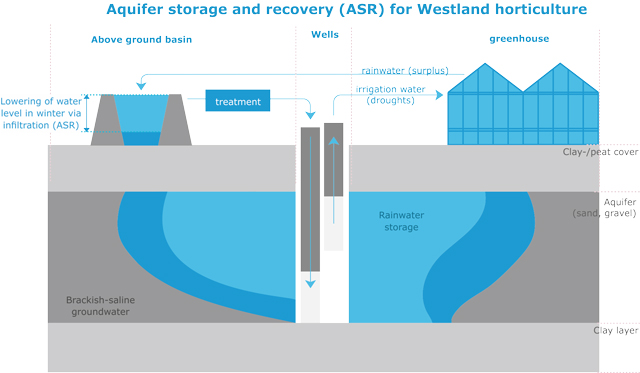

ASR-Coastal enables storage of fresh rainwater in brackish aquifers and unmixed return it for use as irrigation water.

ASR-Coastal enables storage of fresh rainwater in brackish aquifers and unmixed return it for use as irrigation water.

The Freshkeeper was the first in a series of new concepts for improved freshwater management in coastal areas. Two other examples are ASR-Coastal and the Freshmaker.

ASR-Coastal makes it possible to store freshwater in a brackish subsurface and afterwards reclaim it unmixed. The concept is developed by KWR in cooperation with Dutch horticulture farmers and installers and was tested in a pilot on several locations in the Netherlands. Crucial is the way of recovering the freshwater from the brackish aquifer: only with multiple individually controllable filter screens it is possible to pump a large part of the infiltrated water unmixed for direct use on demand. But the application reaches beyond. At this moment it is considered to also apply other freshwater sources, such as treated effluent from the food industry or even treated sewage effluent.

The Freshmaker combines the concepts of the Freshkeeper and the ASR-Coastal. With use of the Freshmaker the naturally occurring, but thin freshwater lens under agricultural parcels in Zeeland in winter can be enlarged to better cover the freshwater demand in the summer.

On a depth of 15 metres a horizontal well abstracts brackish groundwater, making room for the (artificial) infiltration of the fresh (rain) surplus. In summer this additionally stored freshwater is recovered and used for crop irrigation. The Freshmaker has since the summer of 2013 successfully been applied at horticultural farm Rijk-Boonman in Zeeland.

Summary

The principle of the Freshkeeper is that it not only abstracts fresh groundwater, but with the use of a separate filter screen, also the oncoming flow of brackish water. In that way the fresh-brackish interface is stabilised. With respect to the TKI-project Keep It Fresh! a test with a ‘smart well’ is carried out. The smart part being the control and measurement technology. In the end the well itself determines how much brackish groundwater is pumped and disposed, based on online measurements of the salinity of the groundwater. In ten years Freshkeeper developed from the drawing table to a concept tested in a practical pilot that is subject to international attention.

Literature

Grakist, G., C. Maas, W. Rosbergen en J. Kappelhof, 2002. Keeping our wells fresh. In: Proceedings of SWIM-17, TU Delft. R. Boekleman (ed.), p.337-340.

Oosterhof, A.T., M. van der Valk, J.A. de Ruijter en K.J. Raat, 2012. 'Freshkeeper' supplies separated brackish and fresh water from one well (in Dutch). H2O 2012(12): 14-15.

Ross, P.S., K.J. Raat, D.K. Smith, en W.J. Zaadnoordijk, 2014. Integrated Freshkeeper concept for sustainable water supply. Results Valorius programme, The Collaboration Climate and Weather. ARCADIS / KWR, report 077716526:A. Rotterdam / Nieuwegein, 229pp.

Van der Valk, M., 2011. A fresh-keeper for Noardburgum. The future for a salinated well field? Afstudeerscriptie opleiding Water Management, Technische Universiteit Delft.

Zuurbier, K.G., K.J. Raat, M. Paalman, A.T. Oosterhof, J.W. Kooiman, P.J. Stuyfzand, 2014. How subsurface water technologies provide robust, effective and cost-efficient freshwater solutions. Proceedings of IWA World Water Congress & Exhibition, Lisbon, September 21-26, 2014.

^ Back to start